X6140 universal milling machine, horizontal milling machine, vertical and horizontal dual-purpose milling machine

Keyword:

X6140 universal milling machine, horizontal milling machine, vert

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

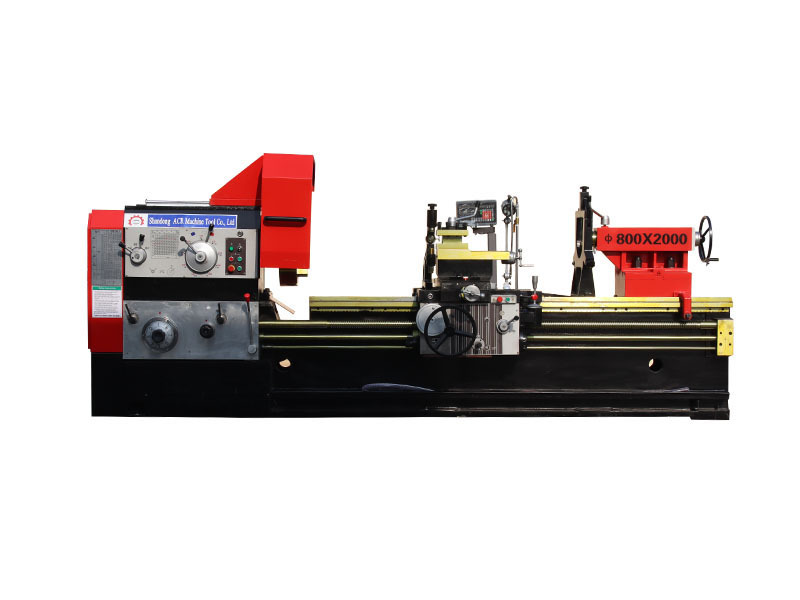

- Commodity name: X6140 universal milling machine, horizontal milling machine, vertical and horizontal dual-purpose milling machine

Machine tool use

The X6140 universal mill is a powerful metal-cutting machine with high stiffness, a wide feed range and the ability to withstand heavy chip loads.

The tapered hole of the spindle can be used to install various cylindrical tools, wafer milling cutters, forming tools, and end mills directly or through accessories.

It is an ideal processing equipment suitable for processing planes, bevels, grooves and holes of various parts, machinery manufacturing, molds, equipment, instrumentation, automobiles and motorcycle industries.

Machine parameters

Technical Parameters

Unit

X6140

working desk size

mm

400 × 1600

Maximum longitudinal travel of worktable (manual / motorized)

mm

900/800

Maximum lateral travel of the worktable (manual / motorized)

mm

315/300

Maximum vertical travel of worktable (manual / motorized)

mm

380/360

Maximum rotation angle of worktable

± 45 °

Distance from spindle centerline to worktable

mm

30/410

Spindle speed series

18 steps

Spindle speed range

rpm

30-1500

Workbench feed level

18 steps

main motor power

kw

11

Feed motor power

kw

1.5

Machine tool dimensions

mm

2556×2159×1770

Machine weight

kg

3850

-

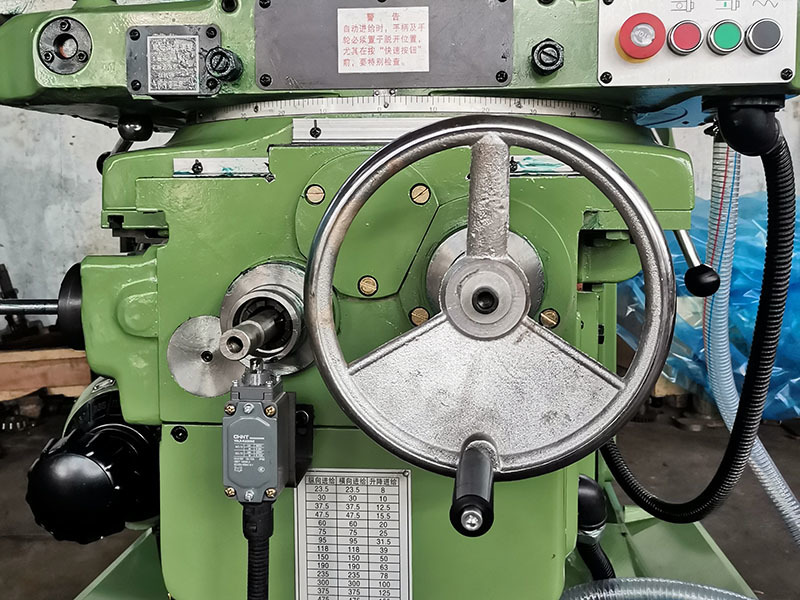

机床特点

1、底座、机身、工作台、滑架、升降滑块等主要部件均采用高强度材料铸造而成,

并进行人工老化处理,确保机器的长期稳定性。

2、机床主轴轴承圆锥滚子轴承,主轴三支承结构,主轴系统刚度高,承载能力高,

并采用主轴动态制动,制动力矩大,停机迅速可靠。

3、工作台水平回转角度为±45°,扩大了机器的加工范围。主传动部分和工作台进给部分

齿轮传动结构,调速范围广,变速快。

4、工作台X/Y/Z可手动进给、电动进给和电动三种快进方式,进给速度可满足不同加工要求;

快速进给工件可以快速到达加工位置,方便、快速加工,缩短加工时间。

5、X、Y和Z方向导轨采用Super Audio淬火、精密研磨和刮擦处理,具有强制润滑,提高精度,

延长机器的使用寿命。

6、润滑装置可对纵向、横向、垂直螺杆和导轨进行强制润滑,并能减少机器的磨损,保证机器的高效运转;

同时,冷却系统通过调节喷嘴来改变冷却液流量的大小,以满足不同的加工需要。

机器设计符合人体工程学,易于操作;操作面板符号设计,简洁直观。 -

序号

名称

数量

1

X向电子走刀器

1

2

数显

1

3

平口钳

1

4

铣夹头

1

5

组合压板

1

6

工具箱

1

7

拉杆

1

8

升降曲柄

1

9

手轮

1

10

进刀手柄

1

11

梅花扳手

1

12

开口扳手

1

13

说明书

1

14

塑料油壶

1

15

一字螺丝刀

1

16

十字螺丝刀

1

17

内六角扳手

1

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection