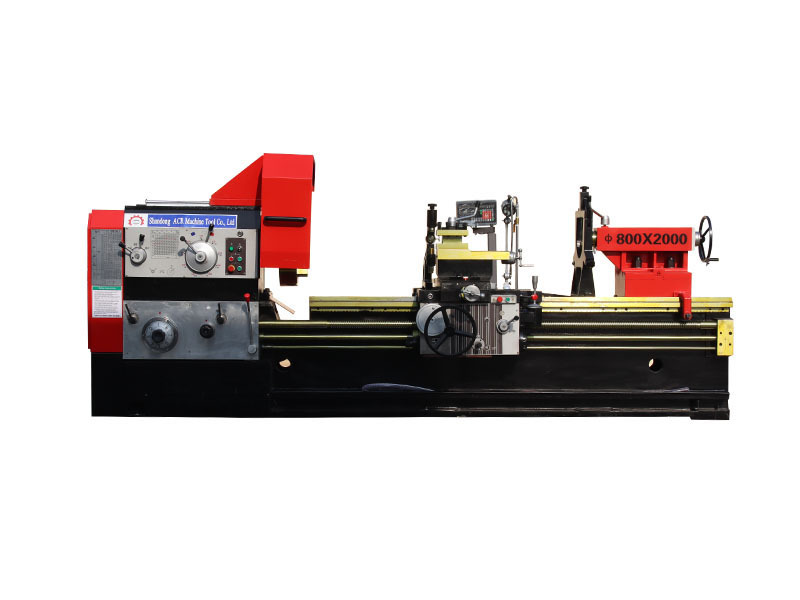

VMC640 Three line Rail Vertical Machining Center

Category:

Keyword:

VMC640 Three line Rail Vertical Machining Center

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

- Commodity name: VMC640 Three line Rail Vertical Machining Center

Product Description:

1. X, Y, Z three-axis travel: 6 00x 40 0x 4 50mm

2. The spindle rotation mode is belt connection, and the maximum speed is: 8,000 rpm.

3. The tool magazine is equipped with 24 disc manipulator tool magazines to meet customer needs.

4. The head group has a heavy-duty box structure with reinforced internal ribs and high rigidity.

5. The spindle cutting method adopts a pneumatic mechanism. During cutting, the spindle is evenly stressed and the bearing life is extended.

6. The electrical box adopts an internal isolation design to separate the heat source part of the controller. A heat exchanger is used at the front to dissipate heat to prevent external dust from entering the electrical box; a fan is used at the rear to dissipate heat for the heat plate.

7. The three axes use high-precision ball screws, combined with precision nut pre-loading and tail-end pre-tensioning devices to ensure that the machine backlash and thermal deformation are kept at low values for a long time.

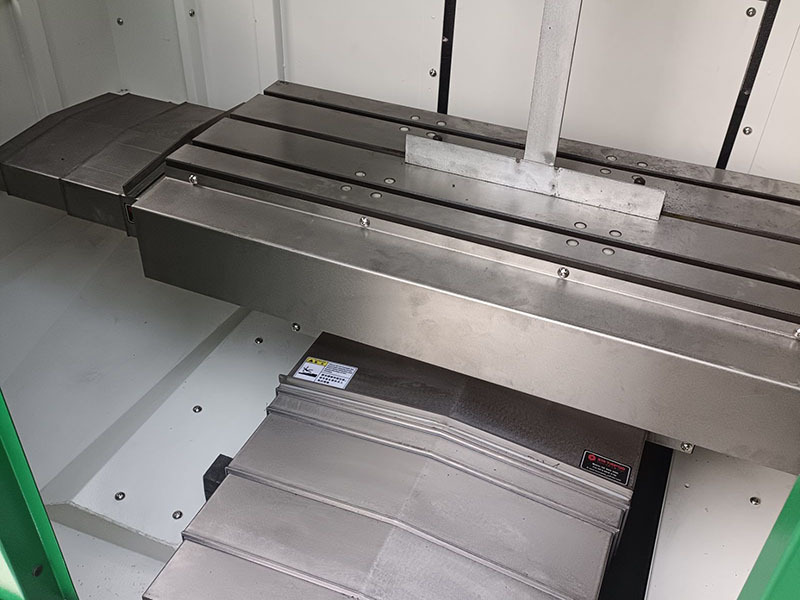

8. The X, Y, and Z axes adopt roller linear guides, which have high rigidity and low noise. They can achieve rapid displacement and obtain cycle accuracy. The rapid movement speed is 2 8/ 2 8/ 2 8m/min.

9. All finished products have undergone laser positioning correction and circular testing to ensure positioning accuracy and servo characteristics. Strict inspection measures are taken before the machine is shipped to ensure that the accuracy of the machine is long-term and stable.

1.Technical parameters

Item Model

UnitUnit _

parameter

working desk size

mm

360x1000 _

X/Y/Z axis travel

mm

6 00/ 40 0/ 4 50

Distance from spindle end face to worktable

mm

120-55 0 _

Distance from spindle center to column

mm

40 0

Maximum load of workbench

Kg

3 00

Workbench T-slot

mm

3-1 6-60 _ _ _

X/Y/Z linear rail specifications

mm

RGH 30

X/Y/Z axis rapid feed

m/min

Third line 2 8/ 2 8/ 2 8

positioning accuracy

mm

0.01

Repeatability

mm

0.008

Minimum positioning unit

mm

0.001

Spindle maximum speed

rpm

8 000

Spindle end taper

mm

BT40-1 20

Fourth axis center height and disc diameter

mm

Optional

Fourth axis specifications

mm

Optional

Four axis motor

KW

Optional

Disc type tool magazine

pcs

16T _

controller system

/

Knd1000

X/Y/Z three-axis feed motor

NM

6 / 7.7 / 15

Spindle motor power

w

3.7

Machine weight

Kg

3 500

Dimensions

mm

23 00x2 00 0x2 3 00

4. Standard configuration

NO

Configuration content

1

CNC system: KND2000MF original system

2

Maximum spindle speed: 8 000rpm

3

Spindle rotation mode: belt

4

Spindle taper: BT40/1 2 0

5

6 00x 40 0x 45 0m

6

Standard configuration: 16- hat type tool magazine

7

Rapid moving speed: 28 , 28 , 28m /min

8

( 1) Cutting cooling system

( 2) Automatic lubrication system

( 3) Cutting blowing device

( 4) Explosion-proof work light

( 5) Three-color warning light

( 6) Horizontal adjustment bolts and pads

( 7) Electrical box heat exchanger

( 8) Three-axis screw pre-tensioning device

( 9) Program storage

( 10) RS232 interface and 5-meter communication cable

( 11) Cleaning device inside the machine: water gun and air gun

( 12) Manual pulse generator: handwheel

( 13) Transformer

( 14) Three-axis telescopic protective cover

( 15) Full cover sheet metal

( 16) Rigid tapping

( 17) Accuracy inspection certificate

( 18) Electrical appliance manual

( 19) System User Manual

( 20) System Program Operation Manual

5. Outsourcing list

No

Product name

Origin

manufacturer

1

Main structure cast iron ( bed )

Domestic

Yunnan

2

CNC controller

Domestic

Kanedi

3

Spindle drive motor

Domestic

Kanedi

4

Three-axis drive motor

Domestic

Kanedi

5

Integral spindle

Taiwan

Dan Quan / Key Chun

6

Booster cylinder

Taiwan

AirTAC

7

X, Y, Z, bearing

Japan

NTN /NSK

8

X, Y, Z ball screw

Taiwan

Silver

10

Three-axis screw pre-tensioned nut

Taiwan

Silver

11

Three-axis coupling

Taiwan

Silver

12

Centralized automatic lubrication system

river valley

13

Three axis wire gauge

Taiwan Bank of China

Roller /Ball

14

Disc robot knife

Taiwan Okada

BT40-16 _

15

Air source filtration and purification equipment

Taiwan

AirTAc

16

cooling device

China

Luokai /Jianyang

17

Electronic handwheel

China

Domestic

18

Electrical appliances, overload protectors

Tracy

19

heat exchanger

China

Wenheng

20

fourth axis

Taiwan / China

Optional

6. Machine tool packing list

serial number

name

Specification

quantity

1

Milling chuck

BT40 ER32

1 set

2

Latin

1 item

3

Adjust the horn

6 sets

4

Anchor bolts

M20x300

6 sets

5

Allen wrench

5, 6, 8, 10

1 piece each

6

Dumb wrench

S17-19/S22-24

1 piece each

7

CNC system

1 set (random)

8

user's Guide

1 copy

9

Certificate

1 copy

10

CNC system operation manual

1 set

11

Tool change bracket

1 item

12

air gun

on the machine

1 item

13

Certificate

1 set

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection