VMC1050 CNC vertical machining center

Category:

Keyword:

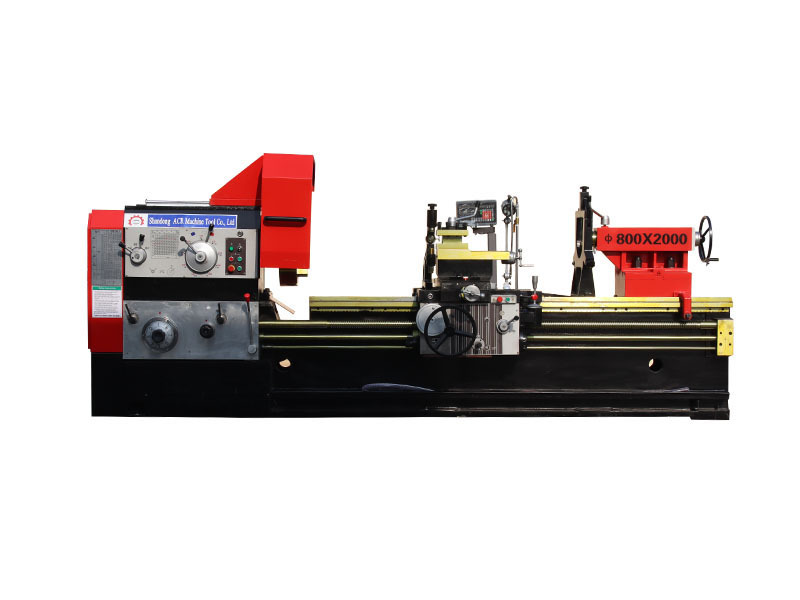

VMC1050 CNC vertical machining center

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

- Commodity name: VMC1050 CNC vertical machining center

1Main structural features of machine tools

1.1 The whole machine has good rigidity and is easy and flexible to operate. It can perform end milling, drilling, enlarging, boring, tapping and other processing processes. It has a wide range of uses and is especially suitable for processing various two- and three-dimensional concave and convex models with complex shapes and complex cavities and surfaces. It is more suitable for batch processing of parts in enterprise production workshops. It is suitable for processing small and medium-sized boxes, covers, plates, shells, disks and other parts in high-precision molds, automobiles, motorcycles, aviation, aerospace, instrumentation, light industry and textile, electronic instruments and machinery manufacturing industries. It can perform end milling, drilling, enlarging, boring, rigid tapping and other processing processes.

1.2 The machine tool base, column, spindle box, workbench and other basic parts are all made of high-strength lost foam casting technology. The internal metallographic structure is stable, ensuring the high stability of the basic parts. The casting structure has undergone machine tool dynamics analysis and finite element analysis to make its geometric structure more reasonable, and the appropriate matching with the reinforcing ribs ensures the high rigidity of the basic parts. The machine tool base is wide and solid, with a fully load-supported design. The structure conforms to the advanced design concept of material mechanics, ensuring heavy load capacity during processing.

1.3 The high-speed and high-rigidity spindle unit is combined with a servo spindle motor; X/Y/Z uses high-torque servo motors.

1.4 X/Y/Z uses high-precision and high-strength ball screws with Japanese NSK ball screw special pair bearings.

2Main technical parameters and main configurations

Machine model

unit

VMC1050

workbench

Workbench size mm

530 * 1000

Workbench T-slot

5-18 * 90

Maximum load of workbench (kg)

600

journey

Left and right stroke (X)mm

1000

Front and rear travel (Y) mm

500

Up and down stroke (Z)mm

600

Spindle

Distance from spindle center to column guide rail mm

579

Distance from spindle end face to work table mm

140-740

Spindle tool holder

BT40

Spindle speed (rpm)

8000

Installation diameter

Φ150

Spindle motor power (Kw)

7.5

servo motor

XYZ axis servo motor (Kw)

3.9

XYZ motor connection method

Direct

XYZ guide rail method

third line

Knives

Tool magazine capacity (tools)

24 disc type tool magazine

Maximum tool weight Kg

8

Maximum tool lengthmm

300

Pull nail model

BT40 45°

Tool holder model

BT40

Fast-moving

XYZ rapid traverse speed m/min

24-24-20

Cutting feed speed m/min

10

XYZ repeat positioning accuracymm

±0.004

Machine appearance

(L×W×H)mm

2920×2400×2700

Total machine weight

(t)

6.0

system

GSK25I

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection