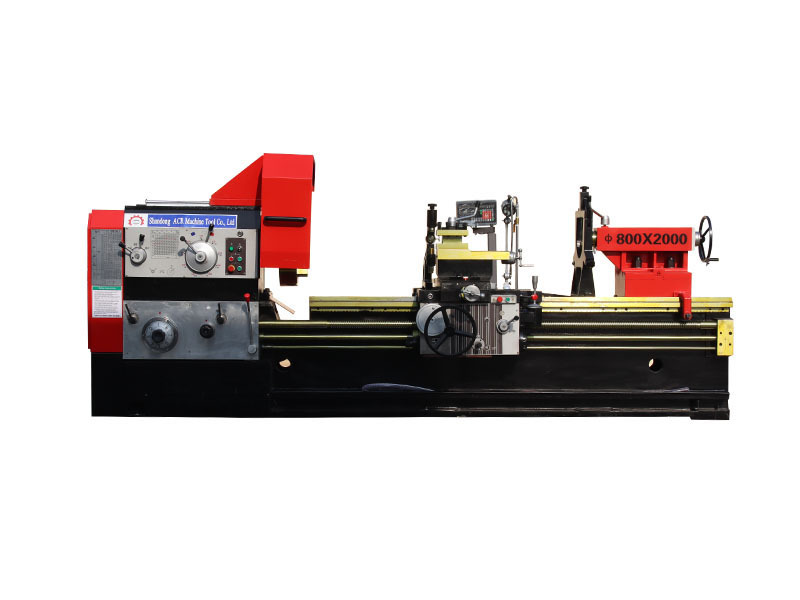

TCK50A inclined bed CNC lathe

Category:

Keyword:

TCK50A inclined bed CNC lathe

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

- Commodity name: TCK50A inclined bed CNC lathe

The main structural features of a machine tool:

1.1 This machine tool is a new product designed by the company in 2023. The whole machine has a compact structure, beautiful and pleasant appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.

1.2 It adopts a 45° overall inclined bed structure. Both the Z/X direction and the tailstock are equipped with high-precision preloaded Taiwan linear roller guides. The tailstock adopts servo drive and hydraulic locking, and the tailstock sleeve hydraulically tightens the workpiece. The machine tool has high positional accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining.

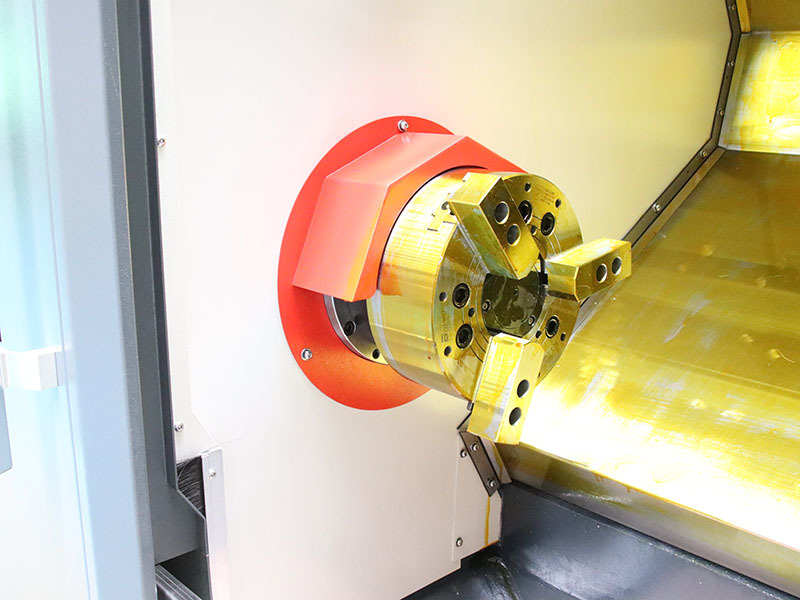

1.3 The spindle adopts a high-precision spindle bearing set and has been precision assembled and dynamically balanced tested to ensure high spindle accuracy, low noise and strong rigidity.

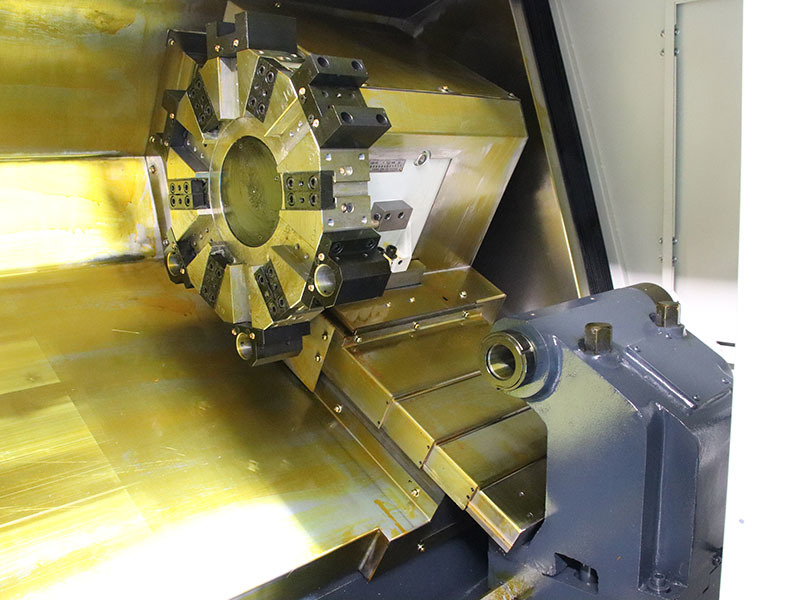

1.4 Using the tool turret method, the tool changing speed is fast and the positioning accuracy is high.

1.5 The X and Z direction feeds use servo motors directly connected to the screw through high-torque and low-inertia elastic couplings to ensure positioning accuracy and repeatable positioning accuracy.

1.6 Adopt advanced centralized automatic lubrication device, regular and quantitative automatic intermittent lubrication, and work stably and reliably.

1.7 Use domestic hydraulic chuck.

1.8 The tailstock is driven by a servo, the linear rail clamp is hydraulically locked, and the hydraulic sleeve is used to tighten the workpiece for processing.

2. Main technical parameters of machine tools:

project

unit

Specification

Remark

Maximum rotation diameter of the bed

mm

Φ 560

Maximum cutting length

mm

500

Maximum cutting diameter

mm

Disc type Φ 400 Shaft type Φ 350

Maximum rotation diameter on the skateboard

mm

Φ 350

Spindle end type and code

A2-6 _

Front taper hole 1:20

Spindle hole diameter

mm

Φ 65

Maximum bar diameter

mm

Φ 50

Hollow chuck available

single spindle

Headstock

Spindle speed range

r/min/Nm

50~ 3500 _

hypersync

Main motor

Output Power

30 minutes / continuous

kW

11

Standard chuck

Chuck diameter

inch

8² _

X- axis rapid movement speed

m/min

30

Rolling guide

Z- axis rapid movement speed

m/min

30

Rolling guide

X- axis travel

mm

210

Z- axis travel

mm

560

Tailstock travel

mm

450

Cylinder drive line rail ( optional servo drive )

Tailstock spindle taper hole taper

Mohs

Mo 5

Standard tool holder form

Horizontal 8-station

Tool size

External round knife

mm

2 5 × 2 5

Boring bar diameter

mm

Ф40/Ф32/Ф25/Ф20

Is it possible to choose the knife from the knife disc nearby?

yes

Machine weight

total weight

kg

40 00

weight capacity

disk type parts

kg

200 (including chuck and other machine tool accessories)

Shaft parts

kg

5 00 (including chuck and other machine tool accessories)

Machine tool appearance

Length ×width×height

mm

2750×2000×1900

Does not include chip conveyor

3. Standard configuration of machine tools and main purchased parts:

Accessory kit name

Specifications and models

Manufacturer

Remark

CNC system

FANUC 0i - TF

FANUC

Japan

Main motor

11KW

hypersync

Beijing

X- axis motor

( with brake )

βiSc12/3000 -B (with brake)

FANUC

Japan

Z- axis motor

βiSc12 /3000

FANUC

Japan

Spindle bearings

90X140X37

import

NSK/NTN (Japan)

100X150X37

100X150X45

X-axis ball screw

φ32×12-635

Nanjing Craftsmanship

Nanjing (optional silver)

Z-axis ball screw

φ32×12-1042

Nanjing Craftsmanship

Nanjing (optional silver)

X-axis guide rail

35 specifications

import

HIWIN (Taiwan) /THK (Japan)

Z-axis guide rail

35 specifications

import

HIWIN (Taiwan) /THK (Japan)

Tailstock guide

35 specifications

import

HIWIN (Taiwan) /THK (Japan)

X-axis screw bearing

25X62X15 _

import

NSK/NTN (Japan)

Z-axis screw bearing

25X62X15 _

import

NSK/NTN (Japan)

Hydraulic chuck

8 inches hollow

KPT

Changzhou

tailstock

Hydraulic tailstock

Domestic

Tailstock thimble

MT5

import

Knife holder

Horizontal 8-station hydraulic tool holder

Domestic

Little King Kong (optional Taiwan Swift)

Cooling chip removal device

Chain plate chip conveyor

Domestic

Optional

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection