TCK46A inclined bed CNC lathe

Category:

Keyword:

TCK46A inclined bed CNC lathe

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

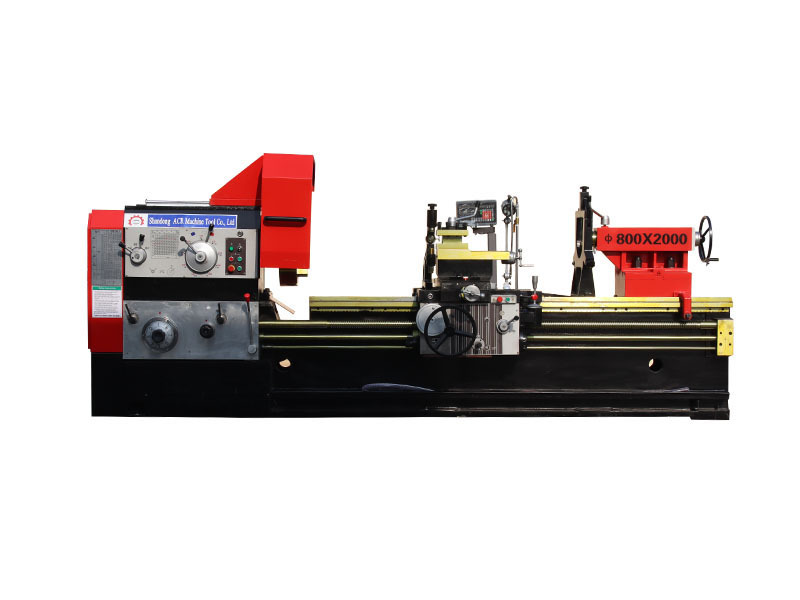

- Commodity name: TCK46A inclined bed CNC lathe

1. Main structural features of machine tools:

This machine tool is a high-speed, high-precision and high-reliability inclined bed machine tool. The main components such as the bed base, bed bed, and headboard are all cast from high-strength materials to ensure the stability of the machine tool for long-term use.

Adopting a 45 ° overall inclined bed structure and equipped with high-precision preloaded linear rolling guides, the machine tool has high position accuracy, smooth chip removal, and is suitable for high-speed and high-precision machining.

The high-speed, high-precision and high-rigidity cartridge-type spindle unit and servo spindle motor can achieve higher spindle speeds; the bearings use a total of 5 angular contact bearings, 3 in the front and 2 in the rear , which are both high-speed and high-rigidity. The spindle unit is assembled in a constant temperature room. After assembly, it undergoes constant temperature running-in for 72 hours. After being put on the machine, it undergoes a continuous 72- hour test run to ensure the reliability of high-speed and high-precision performance.

Using the tool arrangement method, the tool changing speed is fast and the positioning accuracy is high.

The feed in the X and Z directions adopts a C3 -level double-nut preloaded precision ball screw. The servo motor is directly connected to the screw through a high-torque and low-inertia imported elastic coupling. The screw support adopts a pre-stretched structure, which can eliminate transmission Backlash and pre-compensation for the impact of thermal deformation on accuracy during long-term operation of the machine tool ensure positioning accuracy and repeatable positioning accuracy; the use of advanced centralized automatic lubrication devices, regular and quantitative automatic intermittent lubrication, ensures stable and reliable operation.

The machine tool protection adopts a full protection design, which is highly pleasant, unique in appearance, reliable in waterproofing and chip prevention, and easy to maintain.

2. Main technical parametersMachine model

unit

TCK46

Maximum rotation diameter of the bed

mm

Φ 460

Maximum rotation diameter of cross slide

mm

Φ 140

Standard chuck specifications

inch

8 "

X- axis maximum travel

mm

350

Z- axis maximum travel

mm

280/350

Guide rail form

Taiwan Line Rail

Spindle maximum speed

rpm

3500rpm (spindle unit)

Spindle end code

A2-5

Bar material is allowed to pass through (inner diameter of spindle drawn tube)

mm

Φ 42

Rapid traverse speed

m/min

X:15 Z:20

X/Z direction motor torque

NM

X:6 (with brake) /Z:6

Spindle motor power

KW

5.5

Toolbar section

mm

25 × 25

Number of tools

Bundle

8- station hydraulic

X/Z bidirectional positioning accuracy

mm

0.016/0.02

X/Z direction unidirectional repeatable positioning accuracy

mm

0.006/0.006

Overall dimensions (length × width × height)

mm

2100 × 2000 × 15650

Total Weight

KG

2200

3. Main configuration list

name

Specifications and models

quantity

brand

Origin

Remark

Control System

980TDC

1 set

Guangshu

Domestic

Spindle unit

φ 140

1 set

self made

Domestic

Dota

1 set

self made

Domestic

Spindle motors and drives

Servo main motor ( 5.5 KW )

1 set

Super synchronous / wide number

Domestic

guide

Linear Guides

1 set

Silver

Taiwan

ball screw

1 set

Qishan

Domestic

Automatic lubrication device

1 set

Domestic

hydraulic station

1 set

Montfort / Elite

Nanjing

Hydraulic chuck

Hollow 8 〃

1 set

ivi business

Taiwan

Hydraulic cylinder

Hollow 8 〃

1 set

ivi business

Taiwan

cooling pump

1 set

Domestic

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection