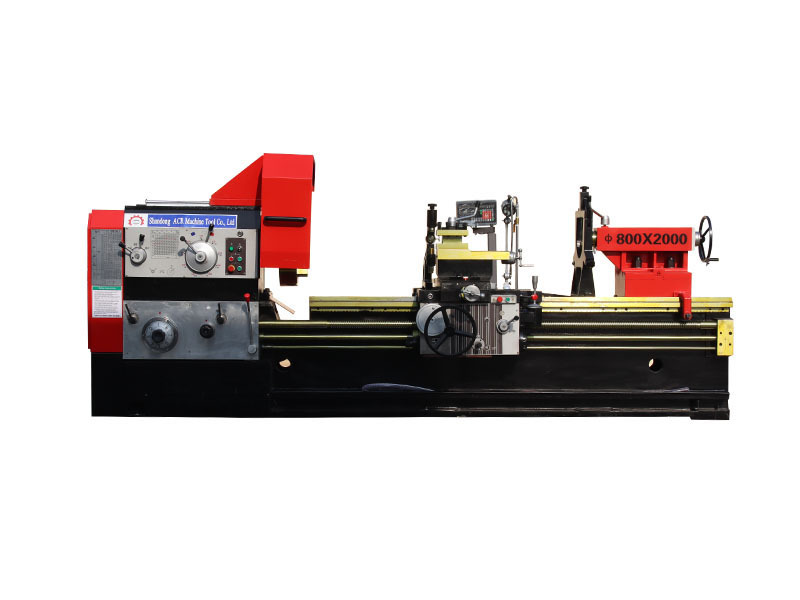

HMC500 horizontal machining center

Category:

Keyword:

HMC500 horizontal machining center

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

- Commodity name: HMC500 horizontal machining center

one. The main technical parameters

Mobile itinerary

Left and right stroke ( X) mm

8 00

Front and rear travel ( Y) mm

65 0

Up and down stroke ( Z) mm

7 00

2. Workbench specifications

Workbench surface size mm

500 * 50 0

Workbench load capacity Kg

5 00

5. Spindle taper hole ( model / sleeve diameter mm)

BT 4 0/Φ1 5 0

Remark:Taiwan-made high-speed synchronous toothed belt drives the spindle, with the spindle speed up to 8,000 rpm and the overall reinforced specially designed bed structure, which is particularly suitable for special processing requirements of high strength, high efficiency, and high-quality surface finish .

6. Spindle speed ( RPM revolutions/minute )

8 000

7. Recommended motor parameters

( Main motor / Kw , A. X , Y , Z axis /Kw )

Spindle 7.5 /1 1 Kw;

X axis 2.2 Kw ;

Y axis 2.2 Kw ;

Z axis 2.2 Kw ;

A rotation axis 1.5 Kw;

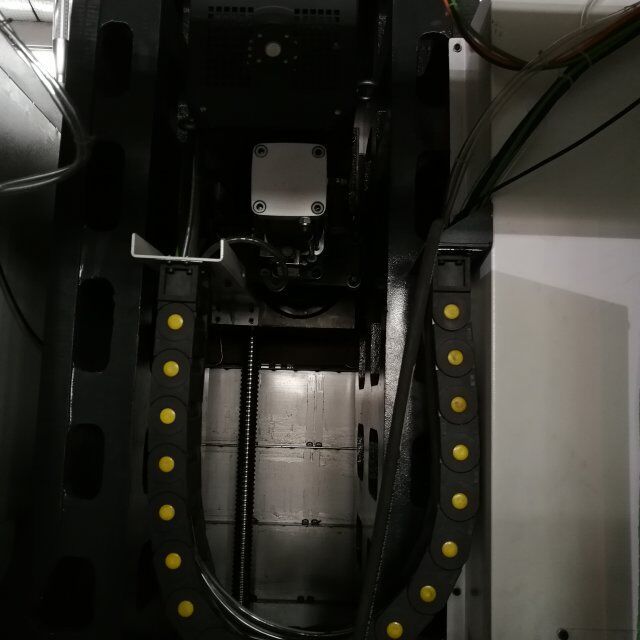

8. Ball screw

X Y Z axis ball screw specifications mm

4012

The three axes adopt Taiwan's P 3 level high-amplitude and precision pre-tensioned ball screws.

9. Connection (transmission) method

XYZ motor connection method

Direct connection (transmission)

Spindle connection method

Belt (drive)

10. Feed speed G00 , G01 (rate)

G00 rapid feed mm/min

Rapid federate

X- axis rapid feed mm/min

24 m/min

Y- axis rapid feed mm/min

20 m/min

Z- axis rapid feed mm/min

24 m/min

11.Roller wire gauge

X-direction roller wire gauge specifications

45

The three-axis wire gauge adopts Taiwan's H-grade high-precision roller wire gauge.

Y-direction roller wire gauge specifications

4 5

Z-direction roller wire gauge specifications

45

Minimum input unit mm

Pulse equivalentmm

0.001

13. Machine tool accuracy mm

Repeat positioning accuracy mm

± 0.0085

Remarks: Machine tool accuracy testing standards (high standards, high precision)

⑴JB/T 8771.2-1998 "Geometric Accuracy Inspection of Vertical Machining Centers"

⑵JB/T8771.4-1998 "Inspection of Linear Positioning Accuracy and Repeated Positioning Accuracy of Machining Centers"

⑶JB/T8771.7-1998 "Accuracy Inspection of Finished Samples of Machining Centers"

⑷JB/T8801-1998 "Technical Conditions for Machining Centers"

Positioning accuracy mm

± 0.010/300

14.Pneumatic system

Air pressure requirement Kg/cm2

≥6

Remark:

The pneumatic system is equipped with a three-point combination, pressure switch, solenoid valve, etc., to realize pneumatic tool change, spindle air blowing, pressure 6-8kg/cm2, flow rate 220L/min, and an external air gun to clean the working area.

15. Cooling system

Cooling system volume L

240

Remark:

Sichuan Jianyang cooling pump, motor power 180W, flow rate 40L/min,

Cutting cooling uses a universal nozzle to spray coolant.

16. Lubrication system

Maximum pressurekg /cm2

6

Remarks: The Valley automatic lubrication device is used to perform forced lubrication on each sliding surface and ball screw; the oil filling time interval and oil filling amount are adjustable; the lubrication tank capacity is 2L. Centralized three-axis bearings and slideways are lubricated.

17. Electric control cabinet cooling system

Hot and cold exchanger

Machine tool standard configuration

Remarks: The electric control cabinet is cooled by a heat and cold exchanger, sealed and dust-proof, with a dust-proof grade of IP65

Electric cabinet air conditioner

Machine tool options

18. Spindle cooling system

air cooling

Machine tool standard configuration

spindle fan

Oil cooler

Machine tool options

spindle fan

19. Electrical system

National standard

Remarks: It complies with the standard of GB/T5226.1-1996 "Industrial Machinery and Electrical Equipment Part 1: General Technical Conditions"; the system has complete and reliable interlocking, safety protection and fault self-diagnosis and alarm functions; it is equipped with RS232 standard communication interface and can be used with a computer Floppy disks are used to store programs (corresponding software can be provided according to user requirements); other systems can be selected according to user requirements; the electrical cabinet circuit adopts national standards, far exceeding the standards of various manufacturers, and still has its stability under harsh use conditions and durable properties.

20.Machine tool power supply

Machine tool power supply voltage range V

AC three-phase 380V ± 10% 50Hz

Total power consumption of machine tools Kva

≤ 20

21. Machine tool appearance dimensions (machine tool protection system) mm

255 0mm* 268 0mm*2 5 50mm

Standard color of machine tools: upper white and lower gray

Remark:

The machine tool protection device is safe, complete and reliable; it complies with GB15760-1995 "General Technical Spare Parts for Safety Protection of Metal Cutting Machine Tools"; the machine tool noise: complies with the national standard <75db

22. Mechanical weight Kg

Gross weightKg

6500

23.Normal usage conditions

Ambient temperature ℃

0—40

humidity %

≤85

Note: Our company is improving the machine at any time, so we reserve the right to change the technical parameters without prior notice. If a contract is signed, the terms of the contract shall prevail.

Main configuration list

serial number

name

Model or drawing number

Origin

quantity

Remark

1

Spindle unit

BT 4 0 (sleeve φ1 5 0 ) belt type

Taiwan Danquan

1 set

2

Pressurized cutting cylinder

45 00

Taiwan Airtac

1 set

3

X- direction ball screw pair

4012

Taiwan Bank of China

1 set

4

Y- direction ball screw pair

4012

Taiwan Bank of China

1 pair

5

Z- direction ball screw pair

4012

Taiwan Bank of China

1 pair

6

X direction ball wire gauge

Taiwan Bank of China

2 pairs

7

Y direction ball wire gauge

Taiwan Bank of China

2 pairs

8

Z direction ball wire gauge

Taiwan Bank of China

2 pairs

9

Special bearings for lead screw

JapanNTN _

6 groups

10

Screw lock nut

M30*1.5

Taiwan Yingxi

6 pieces

1 1

Spindle bearings

Japan NSK

4

12

Flexible coupling

Taiwan

3 sets

1 3

Lubrication system

Single line positive displacement lubrication oil pump

japan river valley

1 set

1 4

Pneumatic system

Triplet 3000

Taiwan Airtac

1 set

15

balanced system

Liquid nitrogen balance bar

Taiwan

1 set

16

Disc tool magazine

BT 4 0/24T horizontal

Taiwan Okada

1 set

17

CNC turntable

TK56 50 0* 50 0 rotary table

Yantai Global

1 set

18

CNC system

KND2000MC1I

Beijing Kaindi

1 set

19

Internal protection

50 0 sleeping plus special

Haidong sheet metal

1 set

20

External protection

50 0 sleeping plus special

Meg Sheet Metal

1 set

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection