CK6150 flat bed CNC lathe independent spindle stepless speed regulation

Category:

Keyword:

CK6150 flat bed CNC lathe independent spindle stepless speed regu

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

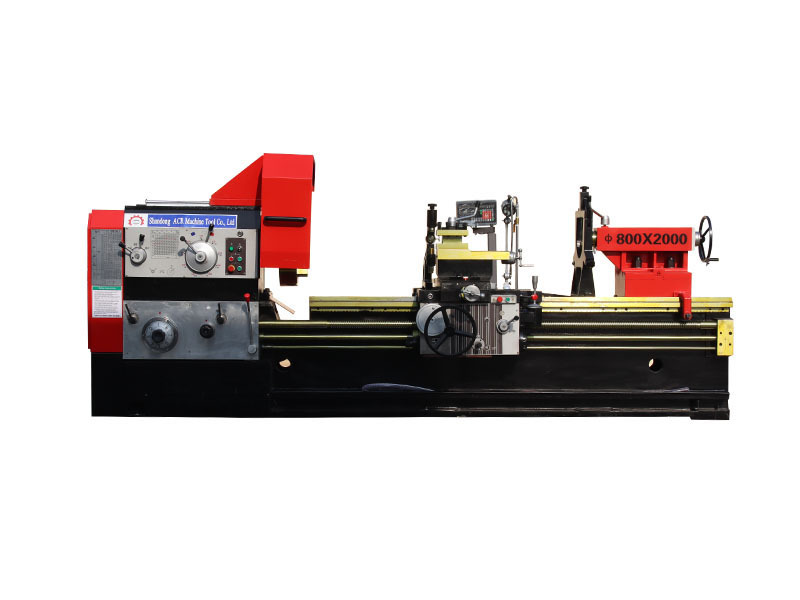

- Commodity name: CK6150 flat bed CNC lathe independent spindle stepless speed regulation

1 Structural characteristics and functional requirements of machine tools

1.1 This series of machine tools is a mature product that the company mainly exports. It has a compact structure, beautiful appearance, large spindle torque, high rigidity, stable and reliable performance, and excellent accuracy retention.

1.2 The optimized design of the headstock is suitable for turning discs and shafts. It can process straight lines, arcs, metric threads, and multi-start threads. It is suitable for turning discs and shafts with complex shapes and high precision requirements. Parts Processing.

1.3 The machine tool guide rails and saddle guide rails are made of hard guide rails made of special materials. After high-frequency quenching, they are super hard and wear-resistant, durable and have good machining accuracy maintenance.

1.4 The CNC system adopts GSK980TC3 system, using domestic famous ball screws and high-precision screw bearings.

1.5 The spindle adopts a high-precision spindle bearing set and has been precision assembled and dynamically balanced tested to ensure high spindle accuracy, low noise and strong rigidity.

1.6 Each lubrication point uses a forced automatic lubrication device to lubricate the screw and guide rail at fixed points and quantitatively . When there is an abnormal state or insufficient oil, a warning signal is automatically generated.

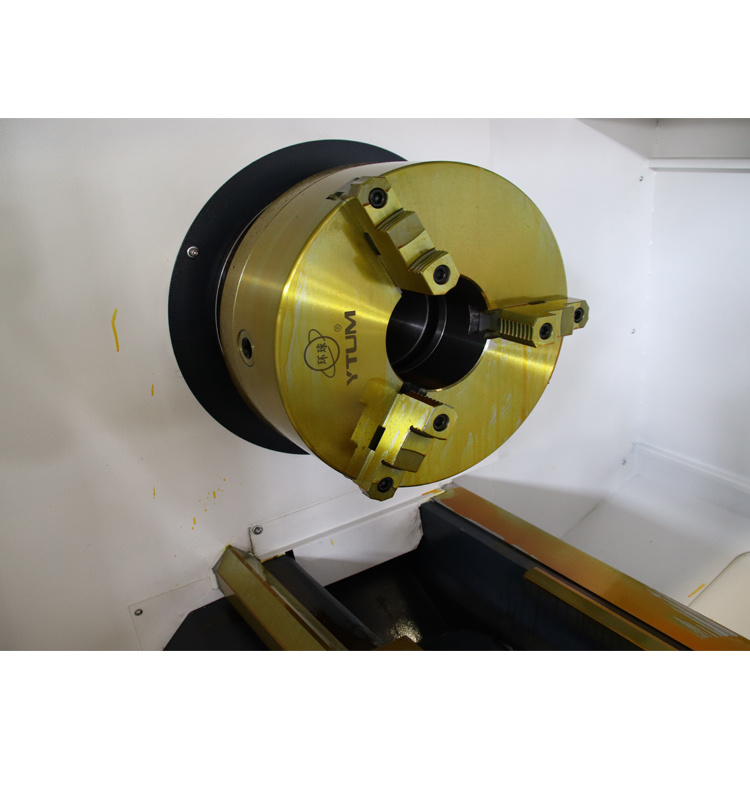

The 1.7 comes standard with a domestic three-jaw self-centering manual chuck.

1.8 The guide rail is equipped with a scraping device to prevent the guide rail from being corroded by iron filings and coolant, and facilitate the cleaning of iron filings.

2 CK6150 main technical parameters and configuration table

serial number

project

unit

parameter

CK6150/1000/1500/2000/3000

1

Maximum rotation diameter of the bed

mm

φ500

2

X guide rail span

mm

210

3

Z guide rail span

mm

400

4

Maximum rotation diameter on the slide

mm

Φ250

5

Needle distance

mm

1000/1500/2000/3000

6

Maximum turning length

mm

850/1350/1850/2850

7

Center high

Distance from bed

mm

276

from the ground

mm

1110

8

Spindle through hole diameter

mm

Φ82 (optional Φ130)

9

Bar diameter

mm

φ80(φ128)

10

Optional hollow chuck tie rod through hole

mm

Φ65

11

Spindle end type

A2-8/A2-11

12

chuck

mm

Ordinary φ250

13

Spindle taper hole taper

No

Metric 90, 1:20

14

Spindle limit speed

rpm

1800

15

Tailstock sleeve diameter

mm

φ75

16

Tailstock sleeve inner hole taper

No

MT5#

17

Tailstock sleeve travel

mm

150

18

Tailstock configuration

Ordinary hand crank

19

Number of knives in electric tool holder

Bundle

4 (optional 6-station or 8-station)

20

Knife size

mm

□25×25(four stations)

twenty one

Lead screw model

X direction

mm

FDC2506-P3

Z direction

mm

FDC4008-P3

twenty two

X/Z rapid movement speed

m/min

6/8

twenty three

X-direction travel

mm

280

twenty four

Minimum setting unit

mm

0.001

25

main motor power

KW

7.5

26

Total power

KW

13

27

Machine tool net weight

Kg

2650/3050/3450/4250

28

Overall dimensions (length × width × height)

mm

2650/3150/3650/4650×1650×1750

Machine tool accuracy standards

Test items

Standard tolerance ( mm )

Periodic axial movement of the spindle

0.005

Radial runout of spindle chuck positioning cone surface

0.005

Position accuracy

Repeat positioning accuracy A

±0.005

Diameter consistency

0.01/150

Flatness

0.025/φ300

Thread pitch product error

0.010/100

Surface roughness

Ra1.6μm

Main configuration list

name

Specifications and models

quantity

brand

Origin

Control System

Guangshu 980T C3

1 set

Guangshu (GSK)

Domestic

Spindle structure

Promise

1 set

Domestic

Screw bearing

Special bearings for ball screws

1 set

Ha axis

Domestic

Spindle motor

7.5 KW

1 set

Domestic

guide

High frequency quenching

1 set

Domestic

ball screw

2506/4008

1 set

north

Domestic

Knife holder

Four-station electric tool holder

1 set

Wenchang / Sanhe

Domestic

Automatic lubrication device

RBCLB-2BZK

1 set

He Jin

Domestic

Three-jaw manual chuck

K11250

1 set

global

Domestic

cooling pump

P=120W

1 set

Domestic

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection