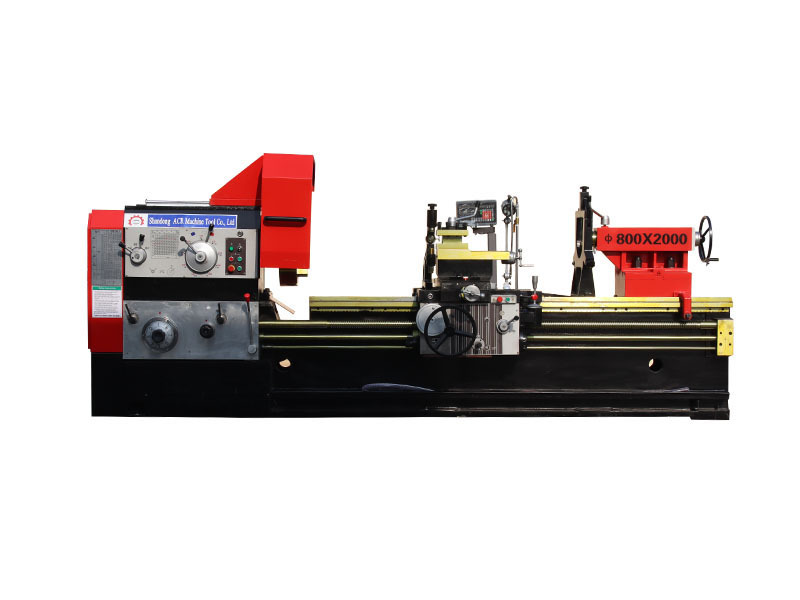

CK6150B CNC lathe with flat bed, manual three gear internal infinite speed regulation

Category:

Keyword:

CK6150B CNC lathe with flat bed, manual three gear internal infin

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

- Commodity name: CK6150B CNC lathe with flat bed, manual three gear internal infinite speed regulation

1. Description of the technical features of CK-6150B three-speed variable frequency segmented speed CNC lathe

Machine tool features :

The castings of this machine tool are all made of resin sand castings and have undergone secondary artificial aging treatment. They have good stability, high strength and stable and reliable accuracy.

The guide rails of this machine tool are precision ground after ultrasonic quenching, with good accuracy and accuracy retention.

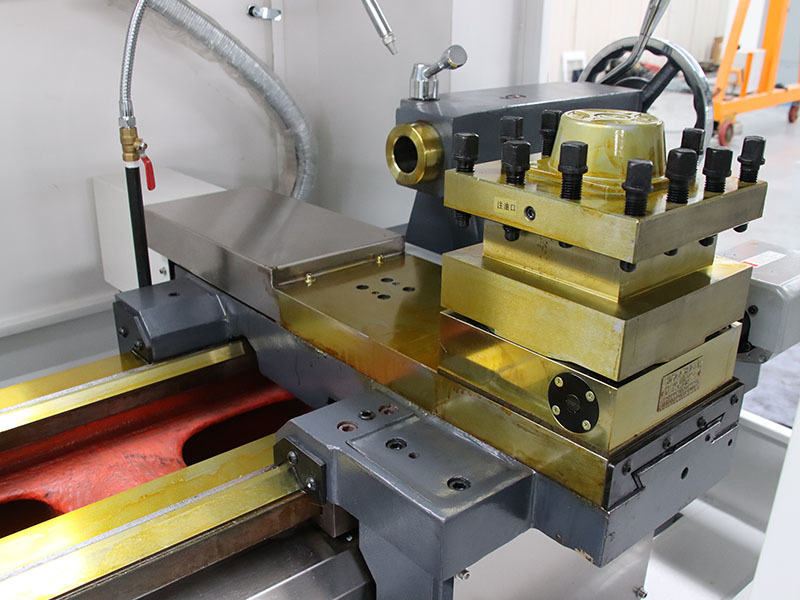

This machine tool adopts an enlarged carriage, which makes the carriage more rigid and the cutting more stable and powerful.

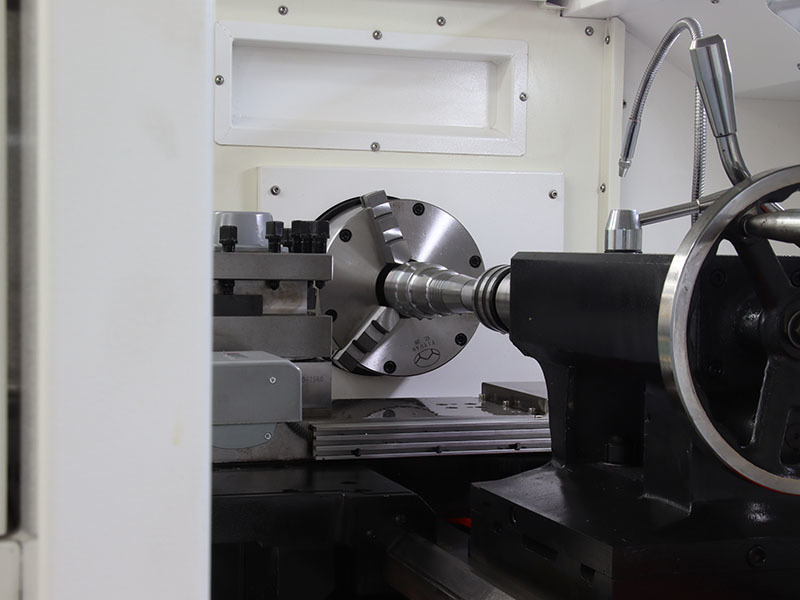

This machine tool adopts a gear spindle structure, with a through hole of ¢82mm and good rigidity. Optional high-precision domestic or imported bearings, high spindle speed.

The spindle of this machine tool has been dynamically balanced, and the smoothness of the parts has been significantly improved.

The main spindle and important parts selected for this machine tool have been strengthened, using well-known brand P5 grade spindle special bearings and KLUBRNBU15 grease lubrication. After the entire spindle is assembled under constant temperature conditions, it must pass computer balance correction and running-in testing. , making the entire set of spindles have a long service life and high reliability.

The ball screws driven by the X/Z axis of this machine tool all use P4 -level nut preloaded ball screws provided by professional supporting manufacturers . The bearings at both ends of the ball screw use P4 -level 60 ° contact angle matched combination special bearings for ball screws. , and the two-axis ball screws are pre-stretched and connected to the feed servo motor by a flexible coupling. The transmission rigidity is strong and the accuracy is stable and reliable.

The machine tool lubrication system adopts an automatic centralized oil supply lubrication system to ensure that any lubrication part is fully lubricated.

2.Use :

This CNC lathe is a high-quality, high-precision, high-performance technology-intensive product carefully designed and manufactured by our company using advanced design ideas and engineering technology. It has good rigidity, high precision, large torque, large processing range, and easy operation and maintenance. , reasonable price and other advantages. This machine tool is widely used for processing steel, cast iron, copper, aluminum and other parts. With the use of an electric tool holder, it can realize automatic and continuous turning of parts such as discs, shafts, threads, cones, etc., as well as drilling, reaming, Reaming and other processing.

2. Main technical parameters of CK-6150B three-speed variable frequency segmented speed CNC lathe

project

parameter

The scope of work

Maximum rotation diameter of the bed

500mm

Maximum turning diameter of the slide

2 8 0 mm

Maximum needle pitch

1000/1500/2000 mm

X-axis (transverse) maximum travel

295mm

Z-axis (transverse) maximum travel

1000/1500/2000 mm

Rail width

40 0mm

X/Z direction ball screw

2505/4010

Fast-moving

X direction 6m/min Z direction 8m/min

Precision

IT6-IT7

Spindle

Spindle head model

A2-8

Spindle inner hole taper /spindle through hole

Metric 90#/¢82mm

Spindle speed

45-180, 180-750, 600-1600

Chuck size

Three-jaw chuck ¢250 mm

Accuracy

positioning accuracy

X-axis (transverse) ≤0.03 mm

Z axis (transverse) ≤0.04 mm

Repeatability

X-axis (transverse) ≤0.0075 mm

Z axis (transverse) ≤0.01 mm

Knife holder

Form /square tool holder specifications

Four-station tool holder /25X25mm

tailstock

Tailstock sleeve diameter /stroke

75mm/150mm

Tailstock thimble taper hole

MT5#

motor

main motor power

7.5KW motor

X/Z axis motor power

5/7.5NM

Machine tool weight /dimensions (1 meter machine tool)

2 7 00KG/3000X1700X1800mm

3. Standard configuration list and brand of CK-6150B three-speed variable frequency segmented speed CNC lathe

NO

name

Specifications or models

Manufacturer /Brand

1

Control System

GSK980TC3

Guangzhou CNC

2

X-axis screw

2505

Domestic

3

Z-axis screw

4010

Domestic

4

Main motor

7.5KW motor

Nanjing Global

5

X/Z direction servo motor

5/7.5NM

Guangzhou CNC

6

Coupling

Domestic

7

Spindle bearings

Harbin Harbin Axis

8

chuck

¢250

Yantai Yiyuan

9

Electric knife holder

Four workstations

Hongda

10

Electrical control components

Tracy

11

Automatic lubrication system

12

Electric cooling pump

120W

13

Mobile hand pulse

With axis selection and magnification

14

working lamp

24V

15

transformer

Guangshu

16

Semi-enclosed protective cover

standard

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection