C6150 horizontal ordinary lathe

Category:

Keyword:

C6150 horizontal ordinary lathe

Telephone:13793702928

- Product Detail

- Feature

- Accessories

-

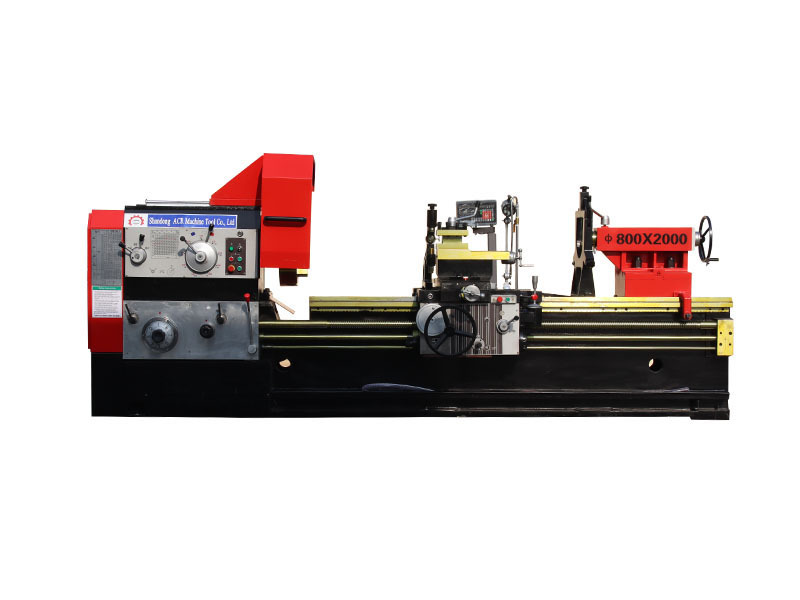

- Commodity name: C6150 horizontal ordinary lathe

1. Machine tool overview:

The C 6150 series ordinary horizontal lathe is suitable for turning internal and external cylindrical surfaces, conical surfaces and other rotating surfaces, turning various metric, inch, module and diameter threads, and can perform drilling and oil groove pulling. It is very versatile. Powerful horizontal lathe, widely suitable for batch processing of various shaft and disc parts.

This series of lathes have medium-frequency quenching on the bed guide surface, making them durable and wear-resistant.

The operation of the machine tool is flexible and centralized, and the slide plate is equipped with a quick-moving mechanism. It adopts single-handle visual operation, which is pleasant and user-friendly.

The structural stiffness and transmission stiffness of the machine tool are higher than those of ordinary lathes, and the power utilization rate is high, making it suitable for powerful cutting.

Before leaving the factory, the machine tools are inspected in strict accordance with the inspection procedures and strong cutting tests are conducted to ensure that the machine tools have good accuracy stability and processing reliability.

2. Advantages of machine tools

The joint surfaces of the machine tool headstock, bed , tailstock, and pallet are manually scraped and ground. The entire machine has been strictly inspected to effectively ensure the accuracy and stability of the machine tool.

The machine tool is made of high-strength cast iron, with special copper and chromium materials added. The quenching depth of the bed guide rails reaches 4mm, which effectively improves the wear resistance and stability of the machine tool.

The machine tool spindle uses Wafangdian bearings, and the machine tool gears are precision ground, which effectively improves the gear hardness and reduces machine tool noise.

Model /main technical parameters

C61(2)36D

C61(2)40D

C61(2)50D

Processing capacity

Maximum rotation diameter of the bed

360

400

500

Maximum rotation diameter on the tool holder

190

230

330

Maximum rotation diameter at saddle

520

560

660

Center distance

750, 1000, 1500, 2000

bed width

360mm

Spindle

Spindle bore diameter

Φ 52mm (optional 82mm)

Spindle end size

C6

Spindle taper hole

MT6

Spindle speed range (number of stages)

40-1400(9steps)

Feed _

Metric thread range (number of types)

0.5-14mm(20kinds)

Inch thread range (number of types)

2-40/inch

Module thread range (number of types)

0.25-3.5mπ ( 11kinds )

trailer _

Horizontal slide stroke

180/222mm

Small tool rest stroke

95mm

Turning tool holder cross-sectional dimensions

20 x 20 mm²

tailstock

Tailstock sleeve taper

MT4

Tailstock sleeve diameter

65mm

Tailstock sleeve travel

140mm

Main motor

4kW/5.5kW

5.5kw

Packing box size: (length x width x height)

Center distance 750mm

2220x1150x1590mm

1000mm

2470x1150x1590mm

1500mm

2970x1150x1590mm

2000mm

3470x1150x1590mm

Weight: Net weight /Gross weight (kg)

Center distance 750mm

1350/2000

1400/2050

1500/2150

1600/2250

1000mm

1450/2100

1500/2150

1600/2250

1700/2350

1500mm

1600/2250

1650/2300

1750/2400

1850/2500

2000mm

1750/2400

1800/2450

1900/2550

2000/2650

Product Video

FAQ

Who are we?

We are located in Shandong, China and have been selling to the domestic market since 2014 (70.00%), Northern Europe (10.00%), Eastern Europe (10.00%), Africa (5.00%), the Middle East (3.00%), and South America (2.00%). Our office has a total of 51 to 100 people.

How do we ensure quality?

Always provide pre production samples before mass production; Always conduct final inspection before shipment;

What can you buy from us?

CNC turning and milling compound lathe, CNC lathe, CNC vertical machining center, CNC vertical milling machine, CNC vertical lathe, gantry machining center.

Why should you purchase from us instead of other suppliers?

We specialize in manufacturing these products for 20 years and have obtained ISO 9001 certification; Ce certification; EAC certification.

Do you have a physical factory?

Yes, we are a CNC lathe manufacturer from Tengzhou City, Shandong Province. We have a professional technical team, sales team, and after-sales team.

Can you customize the machine?

Yes, we integrate design and development together, with experienced engineers and assembly technicians.

What services can we provide?

Accept delivery terms: FOB, CFR, CIF, EXW; Accepting payment currency: USD, CNY; Accepting payment types: T/T, L/C, Western Union remittance; Language: English, Chinese

May I visit your factory?

Okay, we warmly welcome you.

Partners

Related Products

Get a free quote

To: All protection